|

|

Basic Golf Club Building 101

The lessons offered here are intended to be a basic guide for standard club assembly. |

| Tools And Supplies |

|---|

|

|

|

| _Special situations for graphite shafts! First, measure and wrap the shaft tip tightly with masking tape. Then, re-measure and mark the tape as shown. Use a hack saw with a fine tooth blade to cut the shaft half way through. Next, turn the shaft over and finish the cut. Use light pressure, do not allow the shaft to splinter. Remove the tape and use a sharp knife or light sandpaper to lightly scrape 1 1/2" of the tip. |

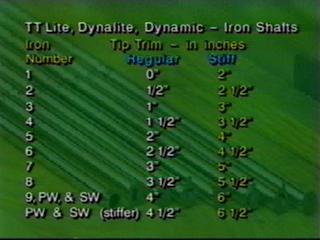

| _In this example we will use the True Temper TTLite® shaft. The measurements presented here are based on the three most popular True Temper® combination shafts, carbon steel (Dynamic) and alloy (TTLite, Dynalite). Alloy shafts are lighter and therefore are used primarily for mid to High handicap golfers. For information on understanding swing weight refer to the manufactures listed below. |

|

_Use the chart to the left or the links below to determine regular or stiff flex for the shafts listed. Remember we will butt trim our shafts to final length later in this process. |

| _As you can see there are half inch increment lengths in our set. To create a regular flex set of irons refer to the first column measurements listed above. To create a stiff flex set of irons refer the second column measurements listed above. This covers parallel combination steel iron shafts and heads at standard swing weight. We used the True Temper TT Lite®, a Combination (Unitized) Alloy shaft intended for use with a parallel hozel iron head in this example. |

|

_Outfitting power equipment for steel shaft cutting can be dangerous! Please be careful to read your owners manual concerning the proper settings for your particular power tool. The proper blade and saw combinations are essential for cutting steel shafts safely and correctly.

Never use a hand held power saw to cut shafts! |

| _In this example we simply use a common tubing cutter to cut the tip of a True Temper TT Lite® shaft. This is a simple inexpensive solution to many of your shaft cutting needs. Simply rotate the cutter while lightly twisting the handle. The best cut is generally achieved by applying only limited pressure to the cutter handle while rotating the cutting wheel several times around the shaft. Steel Shafts Only!!! |

| _Take the chrome finish off of the first 1" to 1 1/8". Some head/ferrule combinations may require more or less material to be removed from the tip of the shaft. This can be achieved with a grinding wheel, hand held file or very rough sandpaper depending on the application. Be careful when using a power tool. Do not burn or "blue" the steel on alloy shafts as this can cause weakness. Our purpose here is to "ruff up" the surface for gluing and achieve a firm epoxy bond. Do not take away too much metal, this may ruin the temper, make the shaft weaker and could even effect swing weight. |

| _Here we see a finished shaft tip ready for gluing. Notice there are no burnt or "blue" spots on the shaft and the edge of our grind will be covered by the hozel of the head. When using a bench grinder, even pressure while turning the shaft quickly will produce the best results. |

| _If the club heads need ferrules you will need to soak them in hot water for 5 min. or until the ferrule is pliable. Slide the ferrule onto the start of the shaft with a small amount of glue just before placing the head on the shaft. |

| _We will determine our final club length after we glue and dry the heads. If you are building a standard set you may elect to trim the butt at this point. A standard length, regular flex set will require 2" to be trimmed from the butt of each shaft. When creating a stiff flex, standard length set it will not be necessary to trim the butt of the shaft. Both of these techniques when used with the proper heads will swing weight standard with out any additional steps. |